Polymeric nanofiber technology as a DDS will be developed in the laboratory as a dosage form for use in the pharmaceutical, food, and cosmetics fields. The ffollowing section introduces the concepts of nanofiber technology and nanofiber production by electrospinning.

Polymeric Nanofiber Technology

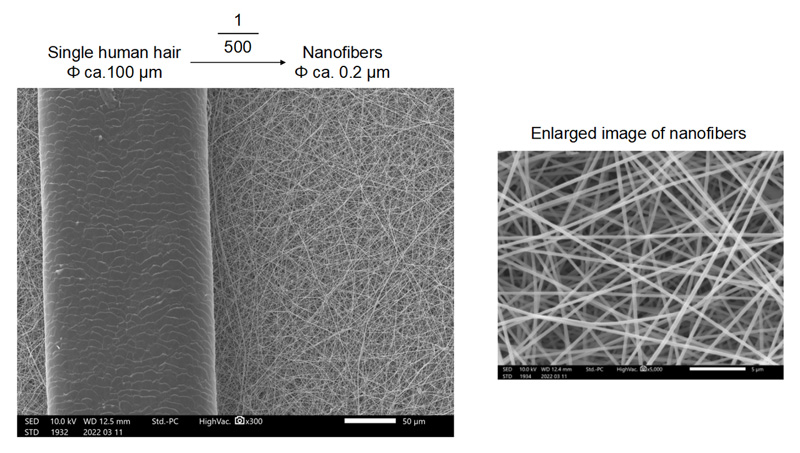

We are engaged in drug development research to develop polymeric nanofibers as DDSs in the fields of pharmaceuticals, foods, and cosmetics. Polymeric nanofibers are several hundred nanometers in diameter (submicron size), about 1/500th the thickness of a human hair. Nanofibers are being extensively studied for both medical and industrial applications. Compared with bulk polymers, nanofibers have a very large surface area because of their small diameter. Sheets (mats) composed of nanofibers are porous, but have interesting physicochemical properties such as improved mechanical properties.

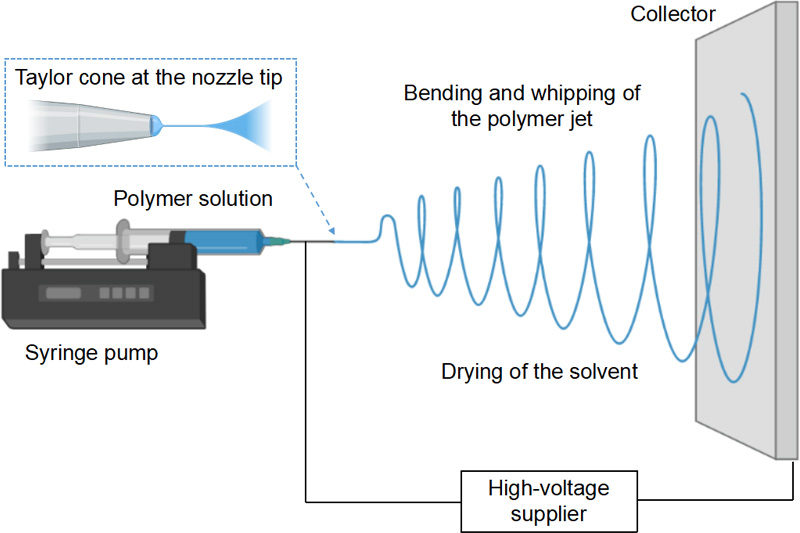

The electrospinning method, commonly used as a nanofiber preparation method, can continuously produce nanofibers directly from liquid raw materials under laboratory conditions. The continuous solidification as fibers without the use of heat is advantageous for applications in the pharmaceutical field, in which physicochemically unstable compounds are often handled.

Instruments

Our laboratories have state of the art instrumentation for pharmaceutical nanofiber design and evaluation.